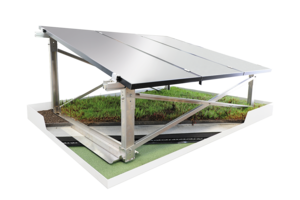

South facing solar substructure Miralux Flex

Simple handling, profitable installation

- Non-penetrative and low-ballast mounting system for flat roof surfaces

- Aerodynamically optimised

- Minimal storage space required, easy handling

- Integrated cable channels

- Additional fixing elements that can be adjusted to hold commercially available panels

- Expandable modular system

Any questions? We are happy to help personally!

+49 5207/9504-5241 request@richard-brink.comThe Miralux solar substructures provide the perfect basis for your flat-roof photovoltaic system. You benefit not only from their quick construction time, but also their easy handling. The Miralux products require minimal storage space and are quick to assemble without penetrating the roof cladding. They feature integrated cable channels and are extremely hard-wearing, made from hot-dip galvanised steel with a Magnelis coating or, on request, from aluminium. All models have been aerodynamically optimised in wind-tunnel tests, reducing the amount of ballast needed.

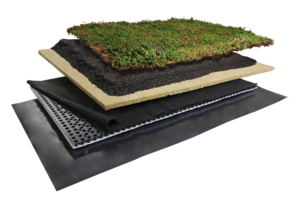

The south-facing photovoltaic substructure depicted here is designed to take advantage of the high performance capacity in the midday hours for a profitable installation. Our latest Miralux Flex model offers even greater flexibility for structuring your photovoltaic systems as standard. Special clamps are used as fixing elements that are fixed to either side of the mounting system. These enable easy mounting of solar panels in a range of commercially available sizes. Ballast supports and two types of screwable ballast blocks (16kg or 34kg) made from polymer concrete are available as accessories, also for installation in gravel or on green roofs.

South-facing solar substructure

| Angle: | Material: | Material thickness: |

| 10° 15° | Magnelis®-coated hot-dip galvanised steel Aluminium (on request) | 1,5 mm |

| Shadow angle: | Lateral distance between modules: | Info: |

| (Standard ca. 20°) | ca. 25 mm | Cable channel: integrated (into the base support) Preservation of structures (optional): EPDM or needle felting (pre-installed on request) Processing time: incl. wiring approx. 12 mins per kWp (two-person installation) |

Frequently asked questions about Miralux Flex South

1. A south-facing version generally enables maximum energy generation. South-facing solar panels can catch the most sunlight due to the position of the sun, which in the northern hemisphere mainly moves in the south. This results in a higher solar energy yield compared to other versions, especially if the panel is positioned at an optimum angle to take advantage of the direct sunlight at midday.

2. The south-facing version is also beneficial in terms of long-term energy generation. As they catch most solar energy in the course of the day, south-facing solar panels are able to guarantee constant and reliable energy production throughout the year.

Key features of the Miralux Flex solar substructures are their exceptional ease of assembly, non-penetrative installation as well as the ability for a range of commercially available panel sizes to be installed and more. Additionally, the systems are made from hot-dip galvanised steel with a Magnelis® coating or from aluminium (on request), which makes them permanently resistant to external influences.

The Miralux Flex systems are designed to save space during transport and on site. Thanks to their prefabricated folding elements, the systems can be assembled extremely quickly and without the need for tools.

Yes, the systems can be easily extended – also retroactively – thanks to the modular construction of the solar substructures.

The systems guarantee excellent structural stability thanks to their favourable flow behaviour, even when exposed to high wind speeds. The ballast blocks, which can also be used on green and gravel roofs, contribute additional stability.

Yes, the systems are equipped with integrated cable channels that ensure that all cabling is safe and tidy.

The products are very lightweight, reducing distributed load by up to 75% compared with traditional systems, without overloading the roof structure.

Yes, the systems have proven lightning current carrying capability, which is essential to the safety of the system.

Indeed, you will not be subject to any warranty obligations for roof surfaces due to the installation of solar substructures if such installation does not require the roof cladding to be penetrated.

Our solar substructures in practice

A stable photovoltaic system in next to no time

Richard Brink solar substructures for residential flat roofs

Gütersloh, 23/11/2023. A project in Gütersloh, Germany, showcases the exceptional functionality of Richard Brink GmbH & Co. KG’s Miralux Flex substructure systems for solar panels, which can be implemented on the roof surface without intensive…

Read moreParapet coverings unite façade elements on the new sports centre in Salzburg

The Sportzentrum Nord sports centre in Salzburg’s Liefering district offers its users numerous training opportunities, including football, basketball and climbing. The new three-court sports hall was completed on the sports area at…

Read moreSolar modules optimally aligned thanks to substructures

A rooftop system for a building’s own energy generation – for many companies, infrastructural facilities and private homes, solar modules represent an extremely economical solution that is also environmentally friendly. To get the most out of the…

Read more

![[Translate to Englisch:] Photovoltaik-Aufständerung "Miralux Flex" in Süd-Ausrichtung. Zeigt die Anbringung der Solarpanels auf der Unterkonstruktion.](/fileadmin/_processed_/6/c/csm_2_Mi_FS_01_a2d2a2eafa.png)

![[Translate to Englisch:] Zwei Ballastierungssteine aus Polymerbeton der Firma Richard Brink zur Ballastierung von Photovoltaik-Unterkonstruktionen. Große Variante mit 34 kg, kleine Variante mit flacher Bodenplatte (16 kg) zum Einbringen in Kiesbetten oder Gründächer](/fileadmin/_processed_/7/d/csm_2_Mi_FS_03_7ee022e237.png)

![[Translate to Englisch:] Ballastierungsunterstützung der Firma Richard Brink. Gekantetes Blech zur Einlage von Betonplatten oder Steinen, um Photovoltaik-Unterkonstruktionen zu beschweren.](/fileadmin/_processed_/9/f/csm_2_Mi_FS_04_cbd6566a7b.png)