Time is a crucial factor especially when installing sizeable photovoltaic systems as it can significantly drive up developers’ costs. However, systems that are easy to handle, and more cost-effective as a result, offer obvious benefits – including for more moderately sized projects. Different conditions in terms of roof surfaces and related planning and assembly requirements illustrate why flexible solutions are needed.

Flexible system for flat roofs

Richard Brink supplied precisely such a solution for an 8.88 kWp system in Gütersloh in the eastern Westphalia region of Germany. The project involved the installation of east-west-facing modules on the flat roof of a residential building to ensure continual energy generation throughout the day. These were to be installed on a base consisting of 15 Miralux Flex photovoltaic substructures made from hot-dip galvanised steel for module widths of 1,000mm to 1,100mm sourced from the metal products manufacturer. These units were additionally factory-fitted with EPDM underlaying protective mats to prevent contact between the structure and the roof cladding. Richard Brink GmbH & Co. KG supplies its tried-and-tested, constantly evolving systems as both east-west-facing and south-facing variants. Both are easy to use and offer maximum safety and security. They have been aerodynamically optimised in wind tunnel tests, making them comparatively low ballast. Installation of the models requires no penetration of the roof cladding, they can be installed quickly without tools, and integrated cable channels guarantee reliable cabling. The system is easy to expand retroactively thanks to its modular structure.

The Miralux Flex model range includes flexible module clamps that can be varied to accommodate a wide range of commercially available panel sizes and are supplied in accordance with customer specifications. After successfully introducing the east-west-facing Flex variant, Richard Brink has now adapted the model so that it also fits the south-facing mounting system. The Miralux Flex products thus now represent the standard for both orientations and guarantee maximum flexibility for every photovoltaic project.

Straightforward ballast options with gravel fills

The fitters installing the modules on the flat roof in Gütersloh – which measured 13.9m by 11.1m – were also impressed by the ballast options. When it came to selecting suitable solutions prior to installation, the project managers prioritised systems that are able to withstand wind and suction without any issues. A further requirement was to realise a stable structure on the flat roof without having to laboriously remove all of the existing gravel fill.

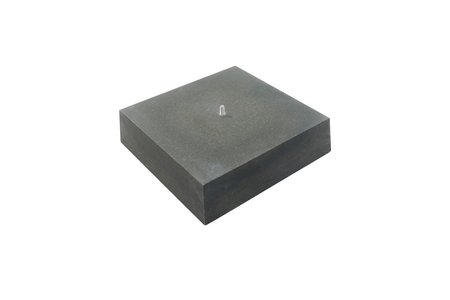

Here, too, Richard Brink’s product range came up trumps as it not only includes the substructures themselves, but also additional optional extras – such as two different ballast block variants made from polymer concrete, also manufactured by the company. Depending on the plan for the required ballast, weights of 16kg or 34kg are available which can be screwed in place directly beneath the solar substructures. The benefit of this is that existing gravel fills merely need to be moved to the side at those points where the ballast is to be installed. The blocks are placed on the roof surface along with suitable structural protection elements and firmly attached to the substructure. This not only ensures highly stable support for the systems, but also a clean look that does not require commercially available paving slabs to be used for ballast. The manufacturer produced and supplied a total of 28 ballast blocks of 34kg and two of 16kg for the Gütersloh project.

The developer was extremely satisfied with both the planning and the outcome of the installation work after the system went into operation in March 2023: “We were impressed with excellent design of the solar substructures from Richard Brink, which enabled rapid and straightforward assembly. The combination of substructure and screwable ballast deserves special mention – this creates an attractive, clean look on the roof,” said Andre Volland-Thurn, who himself is active in roof and façade construction as the Managing Director of Volland-Thurn GmbH.

(approx. 5,100 characters)