Gone are the days of designing bathrooms and showers to be practical and purely functional. Greater emphasis is now placed on aspects such as comfort, design and dimensional accuracy – both for new builds and renovations alike. The Atrium tile-over shower tray produced by Richard Brink is a prime example that simplicity, reliability and highest design standards are by no means mutually exclusive; they also function in symbiosis.

Perfection from a single source

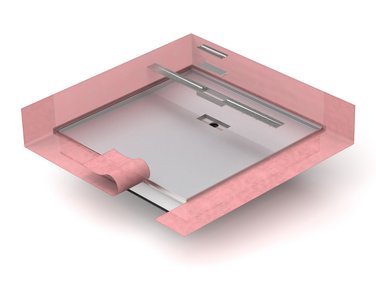

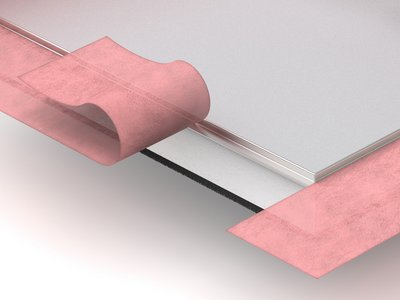

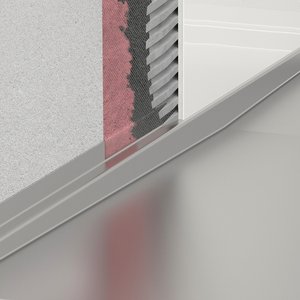

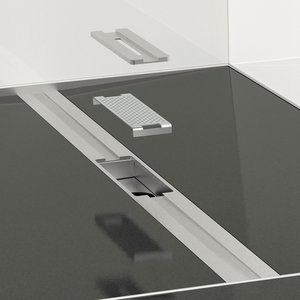

The shower tray’s simplicity is underscored by a number of key properties that make sure the amount of time required for installation as well as subsequent care and maintenance is kept to a minimum. Not only is the stainless-steel tray welded completely watertight, it also features raised edges along all sides which form the transition from the tray to the walls and floor. Appropriate sealing tapes are always supplied with the delivery or, on request, affixed to the tray during production. Moreover, the required gradient is integrated into the stainless-steel tray during production, doing away with the time-intensive work otherwise needed on site. A draining channel made of polished stainless steel is also supplied with the tray and is simply slotted into the base. The channel has an insertable attachment complete with hair catcher that is easily removed for cleaning.

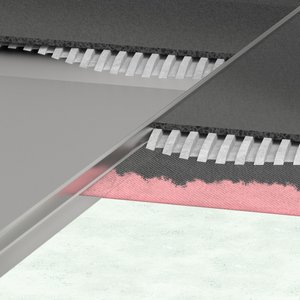

The Atrium’s reliability is ensured by its intelligent construction and well-coordinated components: its base is made up of a sound insulation mat, which sits directly under the lower XPS block complete with cut-outs for the siphon. This, in turn, is topped by the upper XPS gradient wedge and then the stainless-steel tray, which features a 15mm edge on all sides to aid the floor and wall connection together with the supplied sealing tapes. The stainless-steel tray itself is sanded and acts as a holding primer for the tile adhesive. The company Richard Brink has designed its product in such a way that it can either be placed into a recess in the screed or positioned on the floor before the screed is laid. The metal products manufacturer provides a ten-year guarantee on products used in water-carrying areas.

One system for a host of requirements

Thanks to its construction, the shower tray provides an integrated system that fits seamlessly and timelessly into any contemporary bathroom while still being able to cater to individual design concepts. For example, the shower tray comes in three different depths: 900mm, 1,000mm and 1,200mm. With regard to width, customers can choose from standard measurements or define their own widths in line with their specific project requirements. What’s more, the metal products manufacturer from Eastern Westphalia designed the Atrium to hold tiles measuring between 6mm and 12mm thick; on request, it can even be produced to hold up to 20mm-thick tiles.

(approx. 3,460 characters)