Europe’s largest museum on the history of the Hanseatic League is located on the site of its earliest settlement in the north of Lübeck’s Old Town Island. It includes the museum’s new building, the restored historical monument of the castle friary and grounds accessible to the public. Covering around 7,400 square metres, the area stretches from the top of the castle hill down to the street ‘An der Untertrave’. Archaeological excavations carried out during the construction work have been integrated into the exhibition. Visitors touring the museum discover selected stations of the trading network.

Drawing inspiration from historic buildings

The entire project, including architectural planning of the new building, restoration of the castle friary and the exhibition design, was realised by Andreas Heller Architects & Designers. The site’s former buildings, e.g. the city walls, an arsenal or the ‘Witch Tower’ – part of the city fortifications – provided inspiration for the design. The monolithic character of the building is reminiscent of the medieval city walls that once ran along the foot of the castle hill. Jagged, irregular bricks on the façade further the historic-looking appearance. The new building also adopts the contemporary feel of the neighbouring buildings: in the side street leading up the hill, it picks up on one of the gabled town houses typical of Lübeck. One of the most striking patterns of Gothic brickwork is the quatrefoil, a decorative feature incorporated into the gable-fronted façade of the museum.

Reliable drainage required

A covered flight of stairs leads through the body of the main building, connecting the museum’s forecourt on the historic harbour with the castle friary and the outdoor areas above the new building. Precipitation collects at the open head of the stairs at the top and flows down the steps. A reliable dewatering system was needed to prevent water from pooling inside the colonnade. The system needed to be discreet so that it did not detract from the homogeneous surface of the floor and wall areas.

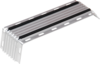

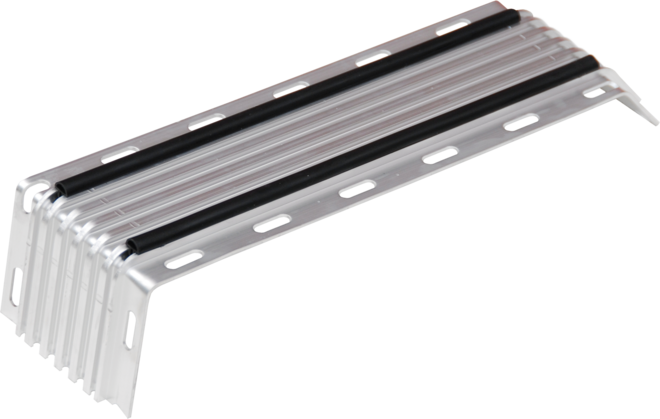

Precisely-fitting slotted channels

The Lamina slotted channels from Richard Brink GmbH & Co. KG fully comply with the required standards. The 1.5mm stainless steel products edge the inside of the colonnades opposite the museum entrance. They are also found in front of the grating at the exit to the museum and in front of the entrance to the function room. In total, 55 running metres of channel were installed. The metal goods manufacturer from Schloß Holte-Stukenbrock customised the slotted channels according to the client’s specifications. The overall height of 200mm and the collar height of 120mm were adapted to the height of the paving. As a result, the system fits exactly into the flooring.

The dewatering system also includes two inspection boxes with run-off pipes as well as two cisterns. These four components were also custom-made in stainless steel. As the boxes have a sufficient height, they can be filled with the paving material. Modules with screw-on handles facilitate opening and cleaning the inspection boxes and cisterns as well as the entire dewatering system.

Preserving a homogeneous surface

The understated design of the dewatering system creates a homogeneous surface inside the colonnades. The channels in front of the entrance are almost invisible, as the slots line up adjacent to the gratings. The result is an attractive design combined with reliable functionality.

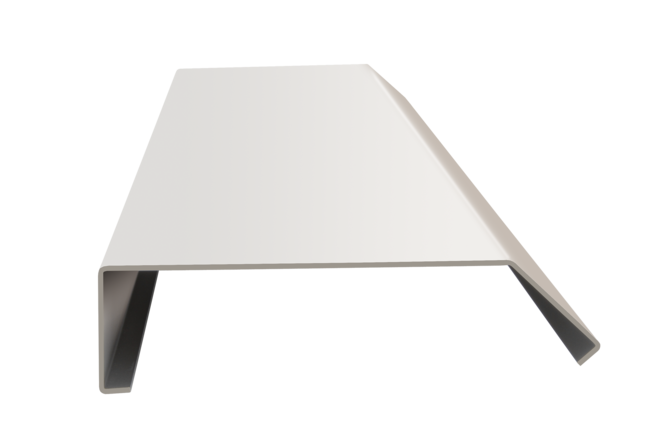

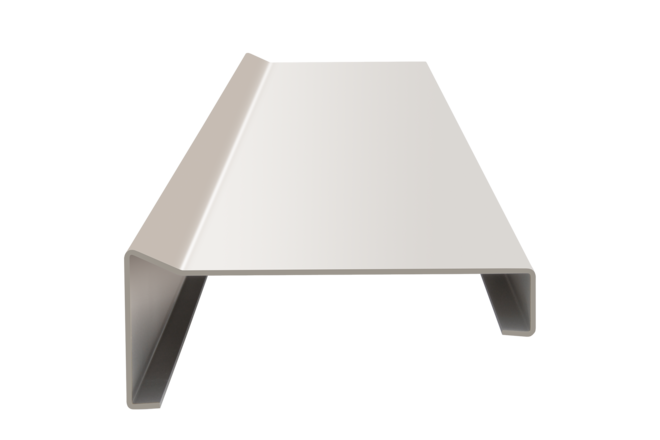

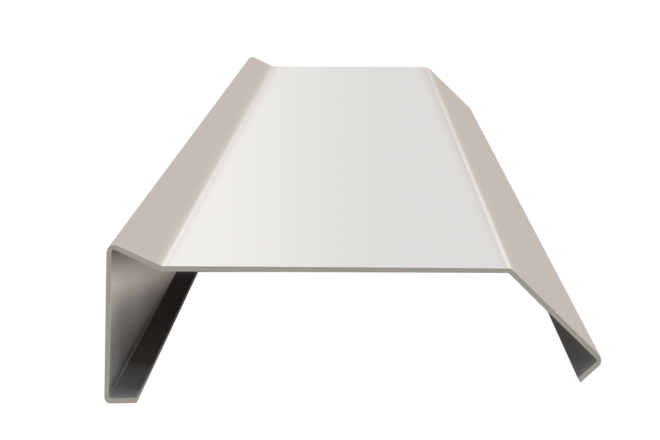

![[Translate to Englisch:] Kantprofil mit innovativem Gummilippenhalter](/fileadmin/_processed_/8/e/csm_2_Attika_Gummilippenhalter2_4bdcdc3bc7.png)

![Vorschaubild: [Translate to Englisch:] Kantprofil mit innovativem Gummilippenhalter](/fileadmin/_processed_/8/e/csm_2_Attika_Gummilippenhalter2_693d9cd14a.png)