Once an industrial site, the Zollverein Coal Mine Industrial Complex has been in the process of restructuring for years as part of a push to repurpose and redesign the site. A comprehensive master plan laid the foundation for creating a lively cultural, commercial and – now with the opening of the Quartier Nord of the renowned Folkwang University of the Arts – educational hub. Teachers, employees and students of the Design Faculty enjoy optimal conditions on the impressive newly developed site, which measures around 19,000 m².

Holistic design concept

Like the building itself, the surrounding outdoor space, which measures approx. 4,800 m², blends in harmoniously with the overall design concept of the Zollverein complex. To achieve this, the responsible project designers, Förder Landschaftsarchitekten from Essen, set special requirements for the design of the outdoor space, including a focus on the architectural ensemble, understated landscaping and the preservation of the area’s industrial beginnings. All design measures draw on the clear geometric and yet variable aesthetic of the architecture and on the basic principles of the master planning.

This approach continues to the rear of the building, where the space was structured and landscaped with a total of 12 raised beds from Richard Brink GmbH & Co. KG. The aluminium custom-made plant systems follow the material qualities of the metal façade of the new building, blending in harmoniously with the look of the site.

Quality made to measure

High-quality, and above all, precisely-fitting elements were needed in order to create a custom landscape for the plateau-like area. So, naturally, plant systems from Richard Brink were chosen. The metal products manufacturer custom-made a total of 197 m long raised beds for the project. Of that, 80 m of raised beds at a height of 110 mm and 117 m at a height of 400 mm were produced. The interplay of different heights creates a spacious effect and lends a relaxing atmosphere at the same time. Depending on the width of the 400 mm-high raised beds, some were also used as edging solutions. Furthermore, the aluminium walls of the raised beds match the colour of the building and blend in well with the white-grey look of the hot-dip galvanised steel elements of the façade.

Simple setup, maximum stability

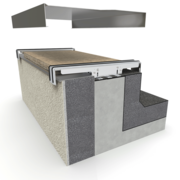

The company responsible for executing the work on the outdoor space, Gerd Linneweber Landschaftsbau GmbH, Dortmund, laid a broad layer of strong gravel down before the plant systems were installed. This gravel layer serves as a stabilising substrate for the raised bed walls and the paved slabs and also acts as a drainage layer for excess precipitation, preventing pooling water.

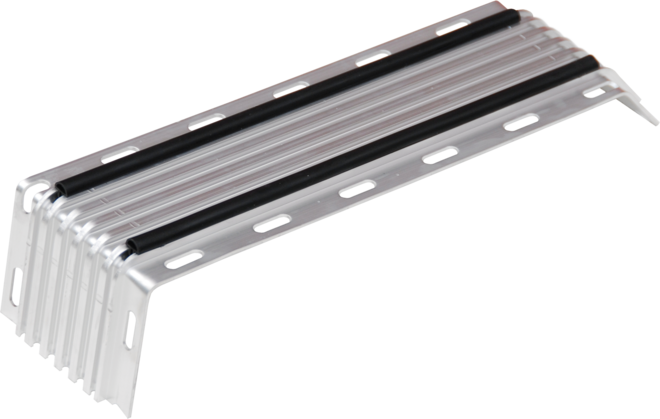

It was quick and effortless to install the raised beds thanks to their custom measurements and the modular ‘plug-in’ system on which they are based. Once the ‘plug-in’ connection is made, the individual elements just need to be screwed together. For beds measuring 400 m or higher, the metal products manufacturer recommends using tie rods and tie rod trays which are provided as standard with the corresponding order. The metal bands inside the beds connect opposite wall to opposite wall and act as stabilisers. This design prevents the raised beds from buckling under the heavy weight of the soil once they are filled.

A mix of trees, shrubs and grass were planted in the 12 raised beds. Trees such as honey locust and red maple form the highest level of growth in the raised beds, with plenty of room for their roots, complemented by buddleia, dwarf arctic willow and rosemary willow as well as feather grass, white wood-rush and Japanese sedge. The combination of different plants guarantees a pleasant environment year-round, thanks to evergreens as well as plants that bloom in the summer months.

A place to feel good

The outdoor space at the back of the building is extensively shielded from the hustle and bustle of the university building and from street traffic, effectively offering students a striking place of refuge with lots of seating and raised bed dividers from Richard Brink. It is a welcome place to go especially on warm, sunny days. The attractive greenery helps give visitors a sense of well-being.

The project managers were very happy with the result of the work and how smoothly everything went: ‘We are pleased with our smooth, successful cooperation with Richard Brink. With the selected materials, the precisely-fitting design and the craftsmanship, the raised beds fully meet our requirements. As an important component of the outdoor space, they blend in perfectly with the overall concept,’ concludes Judith Brands from the design firm Förder Landschaftsarchitekten.

![[Translate to Englisch:] Kantprofil mit innovativem Gummilippenhalter](/fileadmin/_processed_/8/e/csm_2_Attika_Gummilippenhalter2_4bdcdc3bc7.png)

![Vorschaubild: [Translate to Englisch:] Kantprofil mit innovativem Gummilippenhalter](/fileadmin/_processed_/8/e/csm_2_Attika_Gummilippenhalter2_693d9cd14a.png)