The waterpark has been a popular venue at the heart of Bielefeld for more than 80 years. Built in 1927 and refurbished in the 1980s, parts of the structure are now under monument protection. In 1997 the BBF took over various facilities, including the Wiesenbad swimming pool, with the aim of updating Bielefeld’s infrastructure and increasing operational efficiency. Particularly popular elements of the complex include the ten metre high diving platform, while waterslides, water cannons and bubble benches provide a mix of enjoyment and health benefits.

Maintaining the original architecture

Despite bomb damage during World War II and myriad modernisation projects undertaken over the decades that followed, the striking architecture has been preserved to this day. The complex surrounding the open-air swimming pool is defined by a strict axial symmetry. The access road that runs from the north also forms the axis of symmetry and goes up to the centre of the plant building that borders one side of the swimming pool. Diving pools and a children’s pool are separated from the large pool. The building is topped by an amphitheatre-like platform that visitors use as a place to sit or sunbathe.

Showering without puddles

During the summer months, countless visitors flock to the Wiesenbad pool every day, where they inevitably use the sanitary areas. When the facility is particularly congested, large amounts of water accumulate in the showers, resulting in a need for constant and reliable drainage. Channels were needed to take away the wastewater so that no puddles could form. To ensure that this would be effective, they had to run along all of the showers. In addition, it was vital that the channels be completely covered so that the cleaning equipment could reach everywhere in the showers. Moreover, the planners required a solution that was adapted to the clean lines of the building and visually in keeping with the sanitary areas.

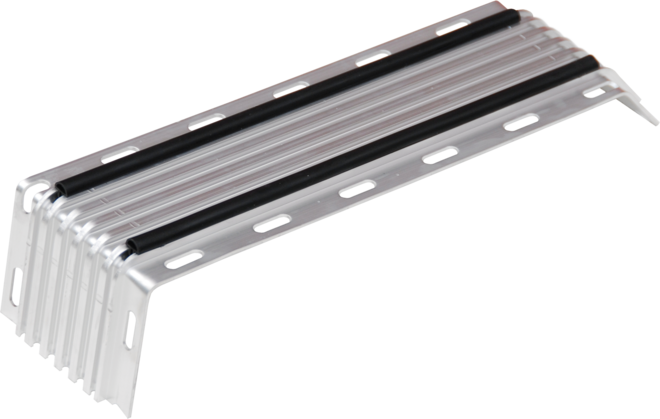

Draining large quantities of water with industrial channels

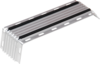

These requirements are met by the 1.5 millimetre stainless steel industrial channels produced by Richard Brink. The metal goods manufacturer developed these channels as its largest type of interior dewatering systems, allowing the continuous drainage of large quantities of water. Employees of HEDRE GmbH installed a total of seven channels in the sanitary areas and in the showers for the changing rooms. Richard Brink adapted both the inlet widths and the channel lengths individually to meet the specifications of the different spaces. Products with inlet widths of 140 and 200 millimetres and lengths of 1000, 2550, 2930 and 4150 millimetres were used. Floor drains with bell plungers and a vertical outflow ensure reliable drainage. Together with 7 x 7 millimetre longitudinal bar gratings, this allowed the height-adjustable bodies of the industrial channels to be inserted into the tiled surface so that they are flush with the floor. As the bars within the gratings are seven millimetres thick, visitors can walk over them with ease, also barefoot. The stainless steel finish of the channels and gratings give the shower areas an appealing look.

Sheer cleanliness thanks to floor-level drainage

Ever since Richard Brink’s industrial channels were installed to drain away the water, visitors to the Wiesenbad pool have been able to take showers without finding themselves standing in puddles. Foam from body care products is also washed straight into the outflow. ‘Feedback from visitors has been very positive. Tidiness and cleanliness make a good impression. They no longer feel as though they’re sharing their shower with the other patrons,’ enthuses Louis Schröter, site manager of the BBF.

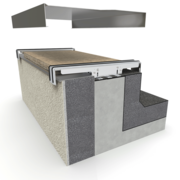

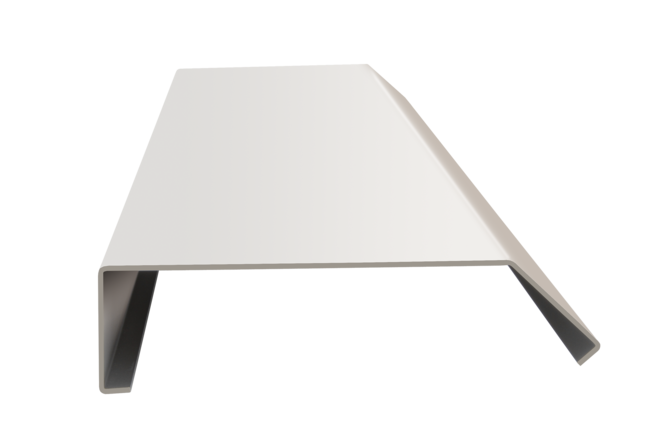

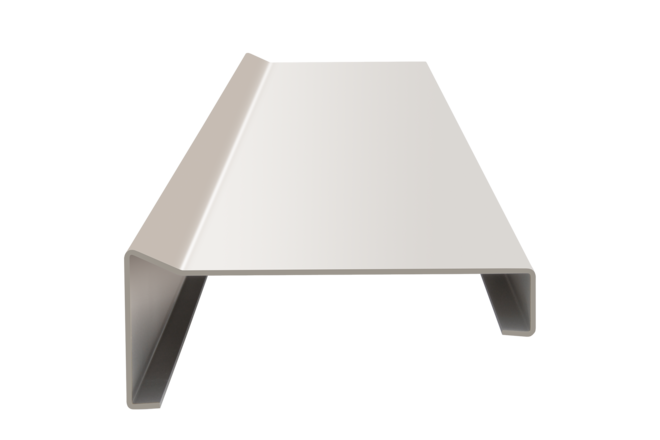

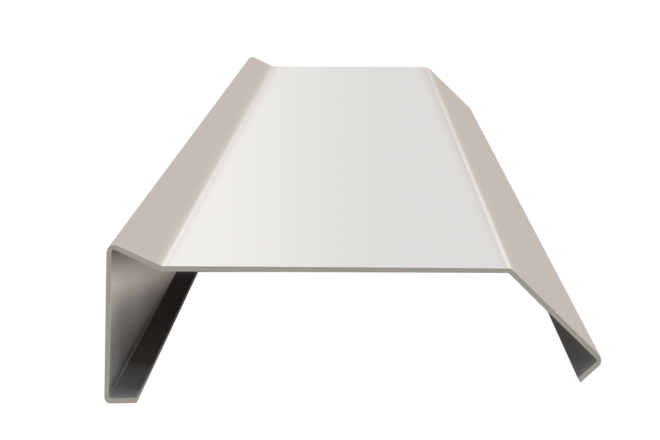

![[Translate to Englisch:] Kantprofil mit innovativem Gummilippenhalter](/fileadmin/_processed_/8/e/csm_2_Attika_Gummilippenhalter2_4bdcdc3bc7.png)

![Vorschaubild: [Translate to Englisch:] Kantprofil mit innovativem Gummilippenhalter](/fileadmin/_processed_/8/e/csm_2_Attika_Gummilippenhalter2_693d9cd14a.png)