Even in Germany, climatic extremes are becoming ever more commonplace. Long stretches of heat without a drop of rain are increasingly followed by periods of heavy rainfall. While dried out and hardened ground even in open and green spaces has trouble absorbing rainwater, sealed surfaces in urban areas and industrial environments are particularly at risk of flooding and the damage this entails. It was therefore necessary not only to create large-scale infiltration areas, but also to break up the sometimes fully sealed paved and concrete surfaces and redesign them in a functional way.

Water pooling as the result of sealed surfaces

Parker Hannifin Manufacturing Germany GmbH & Co. KG found itself facing precisely these challenges. The company is a global leader in the field of motion and control technology with over 100 years of experience in the market. One of their many sites is located in Schloß Holte-Stukenbrock in Eastern Westphalia. Phases of heavy rainfall had become an ongoing issue as the rainwater was unable to seep into and be directed away from the paved surface fast enough. This caused the accumulating water to pool and ultimately find its way into the assembly hall, where deliveries of required components and products are made every day and regularly transported around the hall using vans and forklift trucks. The more water that found its way into the hall, the greater the risk not only of moisture damage, but also of restricting the company’s business processes.

Infiltration across the entire area

The project managers chose to completely redesign the approximately 120 square metres of paved surface, a task they handed to Senner Galabau Jürgenliemke GmbH & Co. KG – a company also based in Schloß Holte-Stukenbrock. The landscape gardening experts worked together with the client to come up with an appropriate plan of action that satisfied the relevant requirements. The entire area was to be levelled at an appropriate height to make drainage easier, before being plastered. A line of channels was to be fitted along the assembly hall to introduce an additional buffer in the event of heavy rainfall. “When choosing suitable dewatering solutions, we placed great importance on ensuring the channels were permeable. Besides this, due to the amount of forklift and delivery truck traffic, the channels had to be absolutely resilient under heavy-duty conditions,” explained Andreas Marxcord from Senner Galabau Jürgenliemke.

The landscape gardeners had already used products from Richard Brink in many of their previous projects. A decision was made in favour of the RigoMax infiltration channels produced by the metal products manufacturer for this project. The installers were already familiar with the functionality and quality of the channels, which were developed with precisely this kind of application in mind.

High-performance, custom-made, gravel-filled drainage channels

Thanks to their bottomless construction, the channels are designed to quickly collect and then gradually drain accumulating rainwater through the gravelled base layers of the respective substrate. They also feature up to two integrated filter inserts. The first insert sits below the grating and features upturned edges that help hold back coarse dirt such as sand or leaves, and even tyre wear particles and microplastics. The optional second insert is able to filter out substances found in the water such as heavy metals, as is often a requirement for public areas.

Richard Brink produces the channels from 4mm-thick hot-dip galvanised steel or stainless steel as standard. Integrated connection braces and angle connectors fixed to the outside walls, designed to be set in concrete, give the RigoMax increased stability. Depending on the grating cover, the infiltration channels are able to withstand wheel loads of between 5 and 10 tons. The channels are available in a standard length of 1,000mm and customers can choose from widths of 388mm, 588mm or 1,088mm and heights of between 350mm and 1,050mm. Other dimensions can also be produced on request with individual lengths and heights. Depending on the version, the channels have a storage volume of between 90 and 970 litres.

Bespoke production for a perfect result

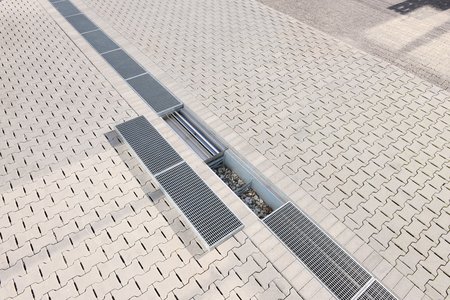

The RigoMax channels therefore offered the best solution for the business premises. The metal products manufacturer supplied a total of twelve custom channel bodies made from hot-dip galvanised steel for the project, each measuring one metre long with an inlet width of 415mm and a height of 360mm. Before the line of channels could be installed along the assembly hall, extensive groundwork was first required due to the products’ XXL dimensions. Once the ground had been dug out to a sufficient depth, the installers placed the required drainage material into the substrate. The RigoMax channels were then permanently encased to either side with the help of concrete. Heavy-duty gratings custom-made from hot-dip galvanised steel sheeting cover the channels. The 30 x 15mm bar gratings were produced in line with the inlet width of the channel and are designed to withstand loads of up to 10 tons. Together with the RigoMax, they meet all the wheel load requirements of the delivery vehicles and forklift trucks that operate on site.

Above all, the team from Senner Galabau Jürgenliemke benefited from the channels’ high level of manufacturing quality. Despite their dimensions, installation was a breeze thanks to the channels’ made-to-measure components. “As always, the entire project progressed smoothly and, in line with the wishes of our customer, on schedule,” summarised Andreas Marxcord. The client also had good things to say about the course of the restoration work and the functionality of the installed products. “Since redesigning the paving and installing the channels produced by Richard Brink on our business premises, even significant periods of heavy rainfall have had no negative repercussions whatsoever. The issues we were having with rainwater seeping into our hall have been efficiently remedied thanks to the competent work of everyone involved. Both the planning and implementation of the measures were to our full satisfaction. The gravel-filled drainage channels from Richard Brink, which were recommended by the landscape gardeners, more than live up to the task at hand here,” praised Peter Trela, Facility Manager at Parker Hannifin Manufacturing Germany, following completion of the project.

(approx. 7,210 characters)