A façade must be intact in order to protect a building’s interior from the effects of wind, rain or frost. On the ground level, drainage or dewatering channels are often used to ensure reliable drainage. They collect precipitation that falls on the façade and redirect it away from the building, preventing water from pooling and avoiding potential moisture damage.

Timely maintenance

If damage such as cracks or unsealed cladding is discovered on façade elements, it must be repaired immediately and properly. But components situated at or below ground level sometimes prove difficult to inspect and repair quickly. Gravel fills or fixed dewatering channels make it harder to access the areas in question. When repairs or renovation work becomes necessary, these elements must first be detached, which is another timely and costly affair.

Loosened in just a few motions

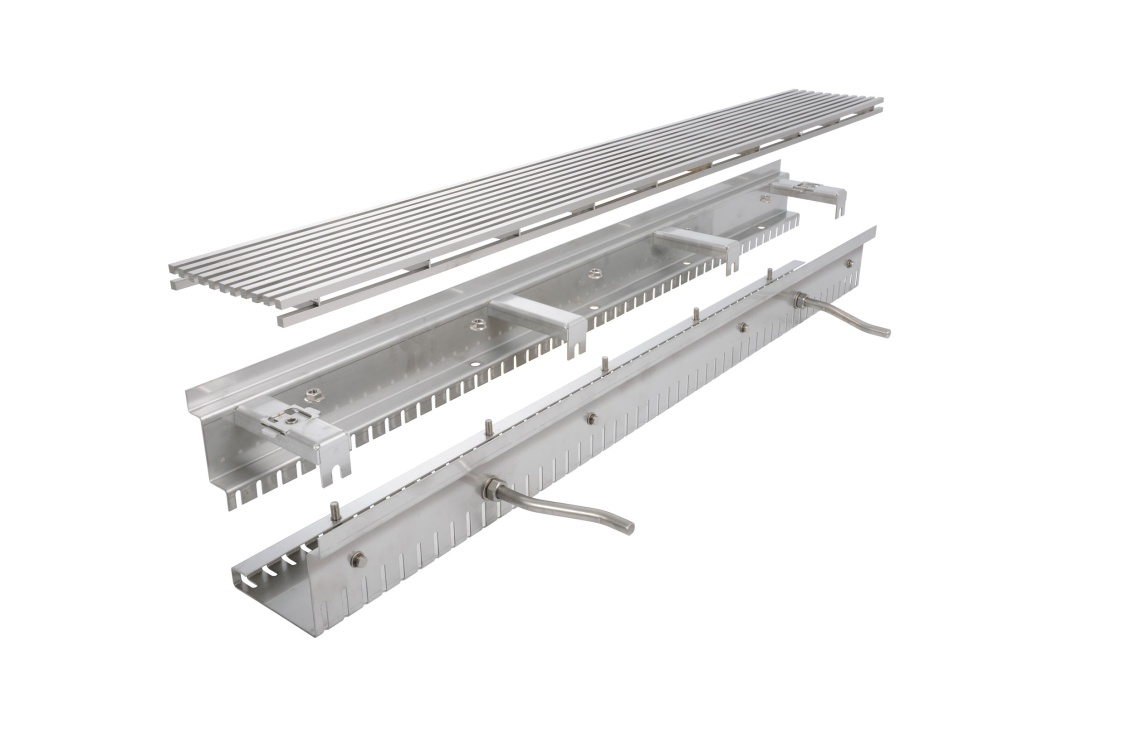

Custom-made products made from hot-dip galvanised sheet steel or stainless steel by Richard Brink provide assistance here. The Stabile drainage channel with removable side represents yet another sophisticated façade dewatering product from the metal products manufacturer. One side can be removed using a fixed or box spanner, allowing for easy inspection of glass panels and other elements of the outer walls. The connection points can also be quickly and easily loosened via fixed bolts. Wall anchors placed in small concrete foundations secure the channel to the side opposite the façade and prevent tilting towards the building. In another design, the channel has an additional façade guide plate that redirects water collected from the façade in a targeted manner.

Custom-made for individual requirements

Since these designs are purely custom-made, Richard Brink manufactures them in any lengths and nominal widths the customer requires. The inlet width starts at 100mm and the minimum installation height is 80mm. In standard production the material is 1.5mm thick, but even versions up to 3mm and different load classes, such as those suitable for surfaces that are driven across, can be produced by the metal products manufacturer in short order.

The custom-made channels can be enhanced through a broad range of cover gratings. The edgings match the standard designs, so customers can choose what they want based on both aesthetic and functional considerations.