Back in the Ancient World, a series of tiered garden structures was built to create the Hanging Gardens of Babylon; today, the Adam living wall produced by Richard Brink GmbH & Co. KG transforms almost any wall into a vertical garden. The metal products manufacturer achieves this with a façade planting system that works for both new and existing buildings. The wall’s modular construction always ensures straightforward assembly, whether on a small house façade or an entire building complex. This is made possible thanks to a range of different substructures and compatible plant cassettes. The latter are made from 2mm-thick aluminium and can be hung from all of the substructures using the hooks provided. This design allows plenty of room for air to circulate, keeping the façade ventilated at all times.

Stability guaranteed

On first launching the living wall, customers could only purchase one type of substructure and one model of plant cassette. Richard Brink has substantially expanded its portfolio since to provide options for various structural requirements and individual design preferences. This has resulted in three structures that can be fixed to the wall. Beyond this, the plant cassettes are available not only in a vertical, but also in a stepped design.

The first substructure is an excellent choice for walls that are able to take a static load of around 140kg per square metre. It is made up of three top-hat rails that are directly screwed to the wall. The plant cassettes are then hung from the rails. A 20mm gap is left between the façade and the cassettes’ outer wall to ensure continuous air circulation. This model has an especially clean look and gives the impression that the plants are floating in front of the wall.

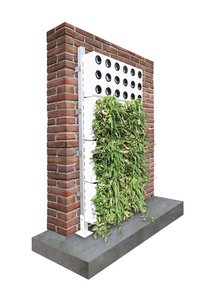

If the façade requires extra support to take the static load, the second substructure is the perfect choice. It features integrated feet that are positioned on and screwed into a foundation. This allows the base to take most of the weight, while special fixtures between the substructure and the wall reliably counter the tipping load of the planted systems. Here, too, the plant cassettes are then hung from the rails integrated into the substructure. This version creates a 115mm gap between the wall and the cassettes for air circulation. It is made for curtain walls with a maximum height of six metres.

The third model is another self-supporting system that achieves an overall depth of 240mm. It is designed to also encompass a layer of 160mm-thick insulation on the wall exterior, which is installed around the wall mount. In this case, however, the added diffusion layer does not sit behind a panel, as is otherwise customary with curtain walls, but the system’s respective plant cassettes. These are again hooked into the substructure and completely cover the insulation that lies beneath.

From vertical to stepped

The metal products manufacturer developed the new stepped version of its plant cassettes to hold the greatest diversity of suitable plants while still enabling excellent rainwater intake. The riveted plant box rows made from 2mm-thick aluminium are slightly sloping, which enables upright planting within a substrate depth of 120mm. They also allow greenery, especially climbing plants, to drape elegantly over the tiers below. The cassettes are attached to the substructure via pre-cut holes, making for seamless, vertical planting across the entire area. Rain and irrigation water is able to seep out through perforations in the base of the plant cassettes. Only the bottom row of cassettes is fully welded during manufacture and comes complete with a run-off nozzle for the controlled drainage of excess water.

Customers can also opt for the original, vertical cassette model, which holds plants through the pre-cut holes, each of which has a diameter of 84mm. The products are fully welded at the front to prevent water leakage. Plastic rings are added to the inside of the holes for a clean finish and the smooth insertion of the plants. While the plants are inserted from the side, the substrate is gradually filled from the top of the cassettes. This type of construction also enables the plants to flourish in just a short space of time, transforming every façade into an abundance of lush foliage.

Simple watering, permanent protection

When it comes to watering, the company Richard Brink recommends commercially available drip irrigation hoses for a reliable and controlled release of water. The hoses are easily secured to the various systems. Each of the plant cassettes features a backward bend with a series of holes along the rear upper section for precisely this purpose. Installed at one-metre intervals, the hoses keep the plants sufficiently hydrated. As additional protection from frost or heat, the vertical cassettes are factory-fitted with XPS panels, which are drilled out in the area of the plant openings and enable easy placement of the desired vegetation on the walls.

(approx. 5,530 characters)

![[Translate to Englisch:] DasAlso a self-supporting system, the third substructure is designed to incorporate a 160mm-thick layer of insulation used on the wall exterior. Photo: Richard Brink GmbH & Co. KG ebenfalls freitragende System der dritten Unterkonstruktion ist für die Aufnahme einer wandseitigen Dämmung mit einer Stärke von 160 mm ausgelegt. Foto: Richard Brink GmbH & Co. KG](/fileadmin/_processed_/7/7/csm_RichardBrink_Adam_05_bc8798be71.jpg)