Trust in more than 45 years of experience

Made-to-measure production from Germany

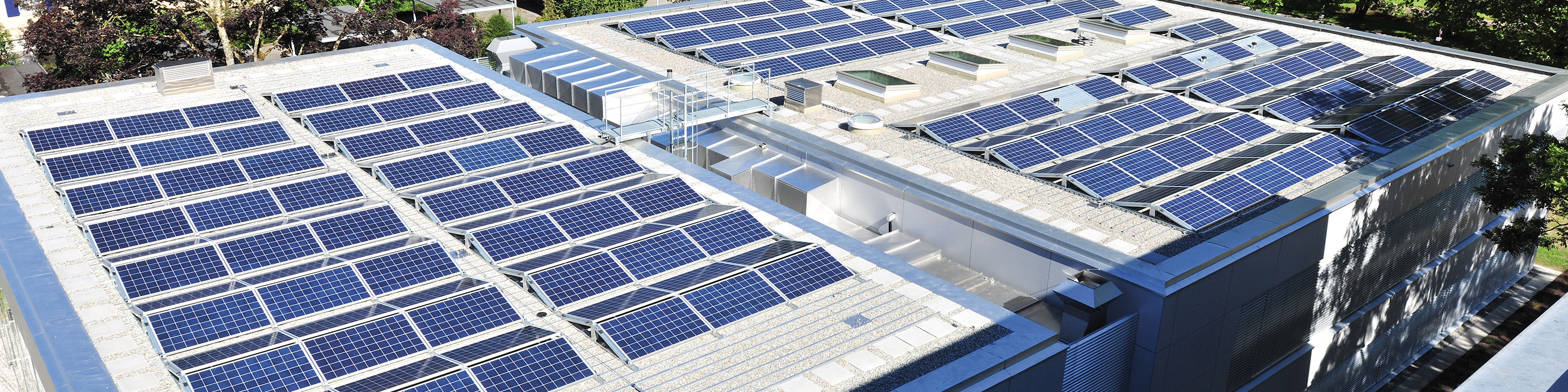

Solar solutions

The best basis for every solar module

Create a reliable base for your photovoltaic project: when putting together private or commercial photovoltaic systems, solar substructures are used to hold the respective solar panels in place. We offer well-designed and absolutely robust fixing elements for flat roof surfaces, made of hot-dip galvanised steel with a Magnelis coating. Benefits to you: our products save space during storage, have been aerodynamically optimised in wind-tunnel tests, require no penetration of the roof cladding, have integrated cable channels and allow for modular expansion.

With the latest iteration of Miralux Flex, we manufacture south-facing and east-west-facing mounting systems. They are all available with fixing elements that can be adjusted to hold commercially available panels. Additionally, two types of ballast blocks are also available, as are ballast supports. An individual ballasting plan for your project is created with the help of an external engineering office. What is more, our portfolio also includes solutions for combining photovoltaic systems with extensive roof planting – for both existing green roofs and also newbuilds!

Discover our range of products of products for fixing solar modules and tap into our over 15 years of experience in the solar industry.

Miralux Flex solar substructure

– east-west-facing with module fixing elements

- Non-penetrative and low-ballast mounting system for flat roof surfaces

- Aerodynamically optimised

- Minimal storage space required, easy handling

- Integrated cable channels

- Additional fixing elements that can be adjusted to hold commercially available panels

- Expandable modular system

Miralux Flex solar substructure

– south-facing with module fixing elements

- Non-penetrative and low-ballast mounting system for flat roof surfaces

- Aerodynamically optimised

- Minimal storage space required, easy handling

- Integrated cable channels

- Additional fixing elements that can be adjusted to hold commercially available panels

- Expandable modular system

Green-roof mounting system for

east-west-facing Miralux Flex

- Mounting systems for east-west-facing Miralux Flex

- Easy to retrofit solar modules on to green roofs

- Combines roof planting with photovoltaics – even for newbuilds

- Additional side plates for maximum stability

- Matching screwable ballast blocks

Miralux Green

– solar substructure for green roofs

- Combines green roofs and photovoltaics in one system

- Well-designed combination for newbuilds

- Extensive green roof surface as ballast for the substructure

- Roof planting and photovoltaic substructures from a single source

- Can be planned as east-west and south-facing variants

Frequently asked questions about photovoltaic substructures

A photovoltaic substructure is a frame or mounting system designed for installing solar modules on a roof or floor. It forms the basis of the photovoltaic system and guarantees that the solar modules are installed securely and stably.

Substructures for solar modules are usually made of hot-dip galvanised steel, stainless steel or aluminium. These materials are robust and resistant to weather influences and corrosion, which is essential for the durability of the system.

East-west-facing solar modules enable energy to be continuously generated over the day because both the morning sun in the east and the evening sun in the west can be taken advantage of. Conversely, a south-facing version seeks to maximise energy generation as it makes the most of the midday sun – when it is at its strongest. The variant that is ultimately selected depends on the specific circumstances and objectives of the project in question.

The requirements under building law vary depending on the region and country. As a rule, the installation of a photovoltaic system must comply with local building regulations in terms of roof loading, fire protection, monument protection and other relevant aspects. We always recommend obtaining an appropriate building permit before starting the project and carefully checking the relevant provisions of building law.

Ballast involves adding weight to the solar substructure to stabilise it and prevent it from moving – or even blowing away – in strong winds. Ballast is typically added by applying special weights or by anchoring the construction to the ground. The precise amount of ballast required depends on various factors, including wind load, roof pitch and the specific design of the substructure. We will work with a structural engineer to draw up a tailored ballast plan for your roof structure.

We offer two different types of screwable ballast blocks made from polymer concrete as well as a ballast support. The blocks, which the company manufactures itself, can be attached directly beneath our solar substructures and are available in 16kg or 34kg variants. The 16kg variant features a flat base panel and is especially suited to systems installed on gravel or green roofs. Commercially available concrete paving slabs and blocks can be used with our ballast support.

Yes, we offer two solutions that can be combined with extensive roof greenery. Our living roof mounting system for the east-west-facing Miralux Flex system enables solar substructures to be installed on both existing green roofs and on newbuilds. Our range also includes the Miralux Green system exclusively for newbuilds. In this case, greenery and PV substructure are securely connected and the granulate and sedum act as ballast for the solar substructures.

![[Translate to Englisch:] Freisteller der Photovoltaik-Unterkonstruktion Miralux Flex von Richard Brink in Ost-West-Ausrichtung](/fileadmin/_processed_/8/9/csm_2_Mi_FS_02_fbfbe5e73f.png)

![[Translate to Englisch:] Freisteller der Photovoltaik-Unterkonstruktion Miralux Flex von Richard Brink in Süd-Ausrichtung](/fileadmin/_processed_/6/c/csm_2_Mi_FS_01_a0f03b2a5c.png)

![[Translate to Englisch:] Freisteller der Gründach-Aufständerung von Richard Brink zur Kombination von Gründach und Photovoltaik](/fileadmin/_processed_/e/f/csm_MiraluxFlex_Aufst_Freisteller_ffaeac8288.png)

![[Translate to Englisch:] Freisteller der Gründach-Solarunterkonstruktion Miralux Green zur Kombination von Gründach und Photovoltaik](/fileadmin/_processed_/2/2/csm_MiraluxGreen_Freisteller_7424b6f1b6.png)